A RENEWED HORIZON FOR PERFORMANCE INSULATION

january 2024 // context

The valley where the hemp farm is located

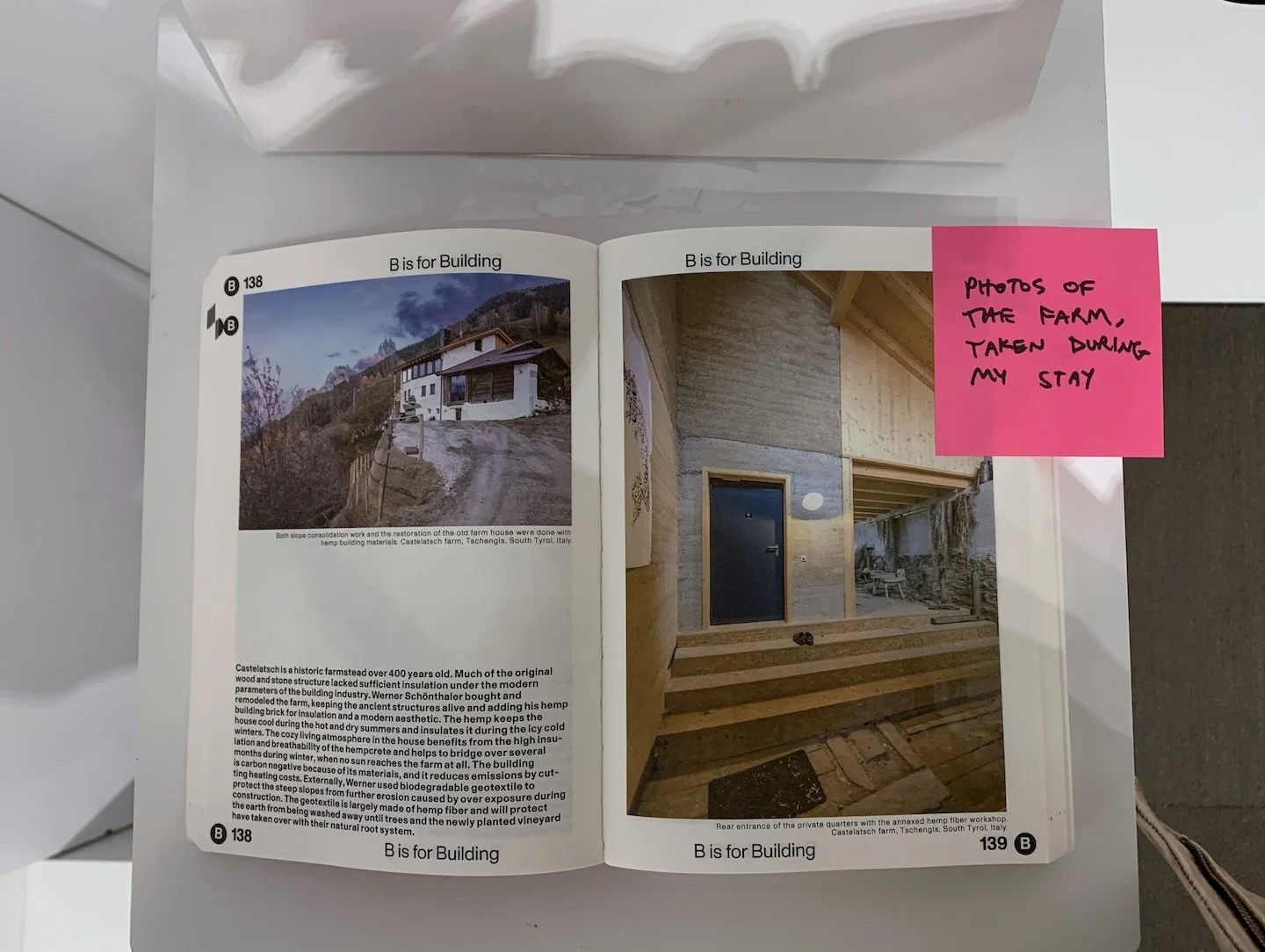

In 2016 I met a German-based photographer named Maren Krings while I was a volunteer on a hemp and fiber farm in South Tirol, Italy. We stayed in touch and in 2022 Maren completed a project called “H is for Hemp”, a photo-journal documentation of 200 projects from twenty-six countries that examines how the renewal of industrial hemp is pushing local economies to prioritize the reuse and regeneration of materials.

In-depth interviews with people connected to these projects —farmers, scientists, engineers, designers, business owners, energy experts, healthcare workers, nutritionists, indigenous educators, policymakers, academic and industry researchers— provide cross-pollinating viewpoints and spotlights the challenges of bringing a circular economy to a global scale.

Also interspersed are Maren’s diary entries during her travels (I am covertly mentioned as “textile designer’ on page 68!) which serve as personal anecdotes to the book's comprehensive findings. The farm where Maren and I met is featured on pages 134-139, along a write up about our farm host and construction company owner Werner Schoenthaler, whose R&D efforts created a carbon-negative insulation material for the building industry.

Werner’s house which is insulated by hemp bricks that his father’s construction company now manufacturers!

While the book was printed as a limited edition run, a digital version will be coming out later this year to make Maren’s research more accessible to a wider audience. I didn’t end up reading the book until this past fall and since then I’ve been itching to share it with everyone in the textiles industry. Who knew that a remote alpine farm in South Tirol would serve as the origin point, years later, for an independent research project on renewable materials?

Given that performance footwear brands (at least the ones I’ve worked for) have a penchant for sleek upper materials, the coarse, straw-like character of hemp would be hard to sell for their consumers, especially when other limitations like color matching and inferior mechanical properties (compared to nylon/poly) make it difficult to justify using on an upper. Instead, could hemp be utilized as an internal technical material? And if so, what could it replace?

An excerpt from Maren’s book, “H is for Hemp”

Conventional Sheetfill Sampling

In lieu of sharing proprietary material samples: behold, a random stock image of insulated materials to get the point across (©U-Long)

While working with a factory partner to sample some quilting materials for a new footwear model, I learned the only three options for in-house sheetfill material were virgin polyester, recycled polyester, or textile shred from a materials vendor.

So I made some quilted samples with textile shred but the material was dense and behaved more like felt. Not lofty nor lightweight... I asked if the factory had any plant-based sheetfills, with a fluttering hope that they provided hemp, but the answer was no 😆 Were there other fibers that could provide the same technical performance (thermal retention, moisture resistance, compressibility, etc) as animal or synthetic down?

A Better Solution

This led me down an obsessive path to contact start-ups and established companies seeking to replace conventional down and synthetics with renewable alternatives. I still have a lot to learn about the outerwear apparel industry, as well as these companies’ efforts to reshape the materials economy, but the notes below are a snapshot of what I’ve researched and documented so far.

Challenges with current industry options for apparel insulation

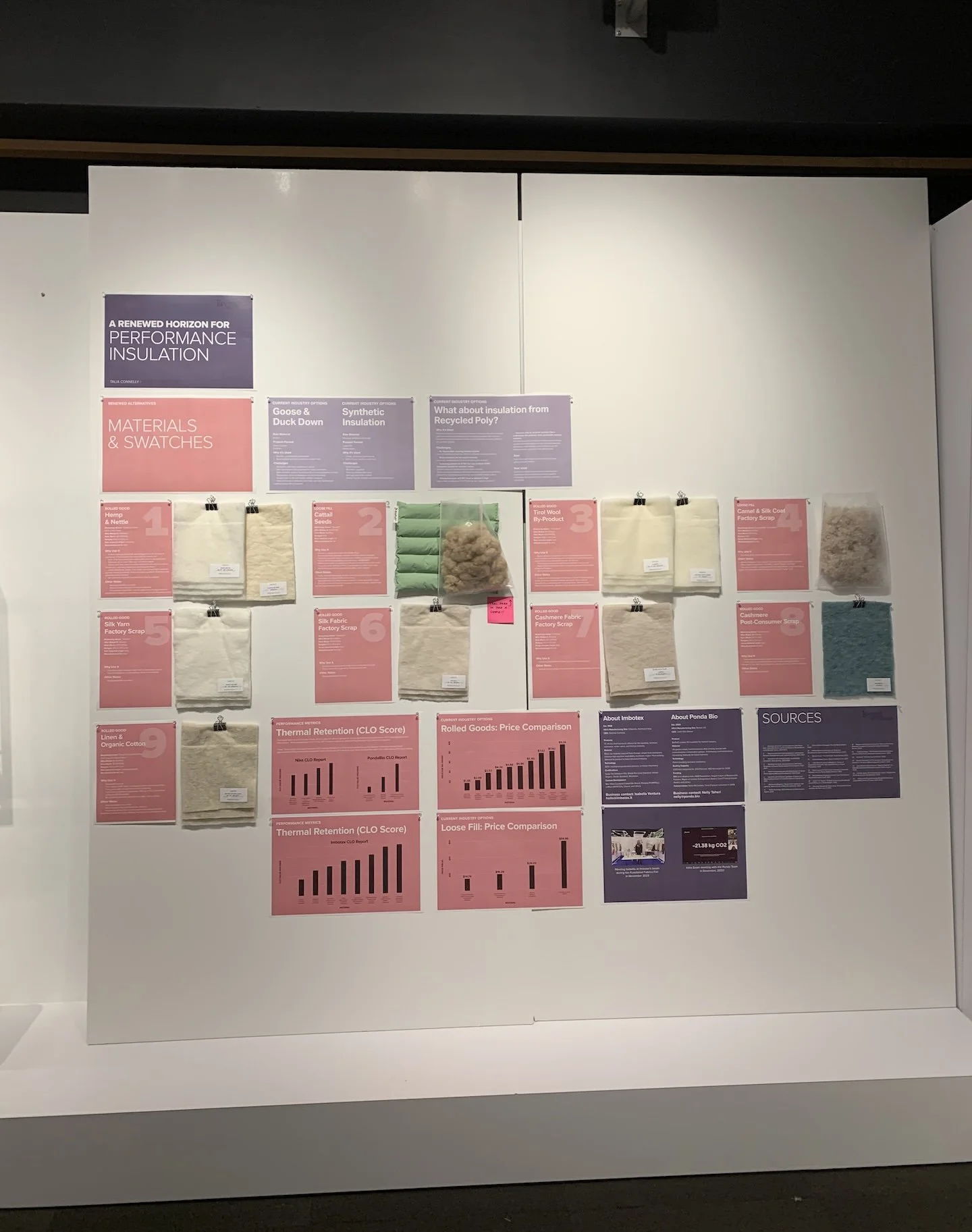

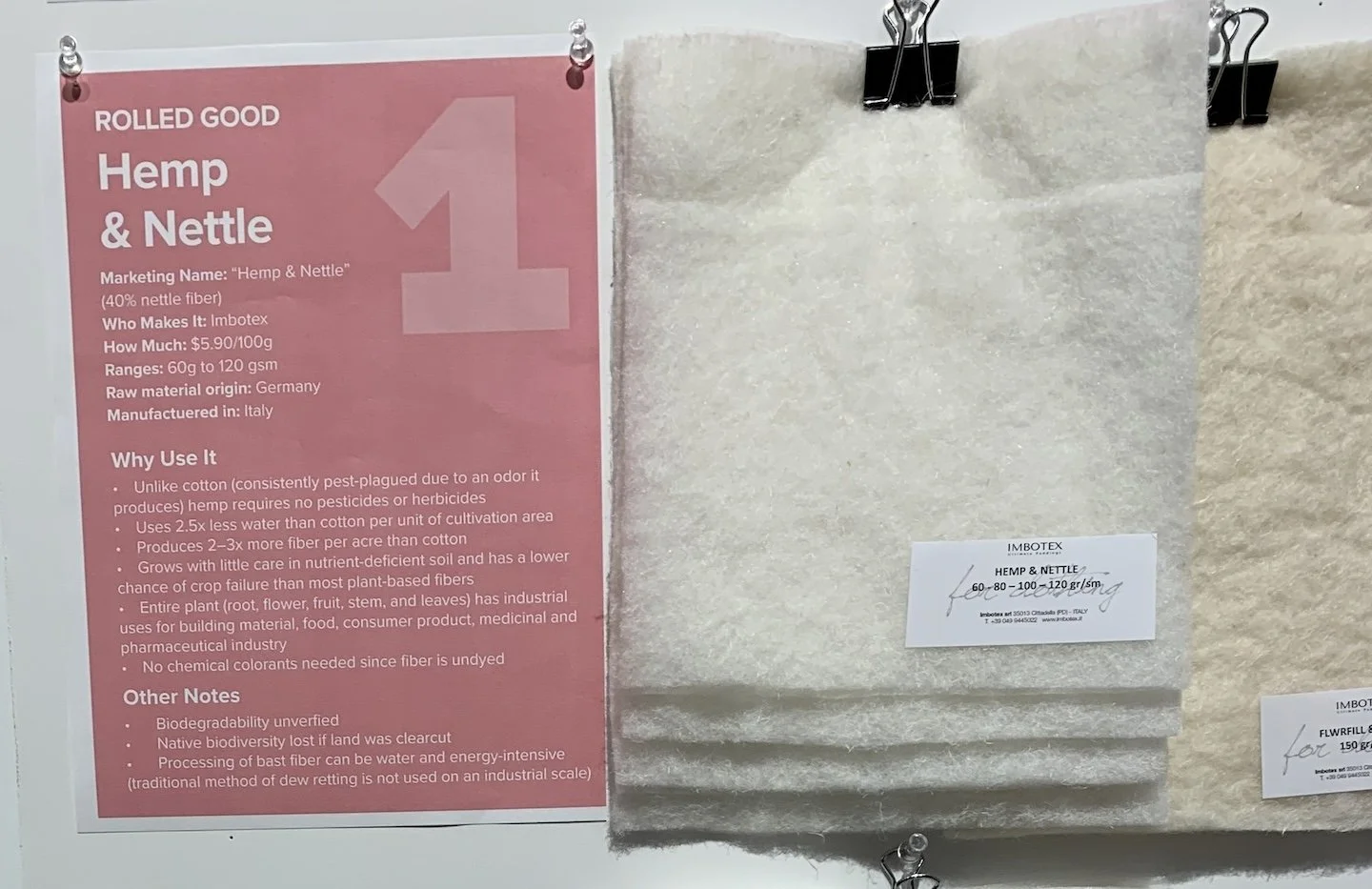

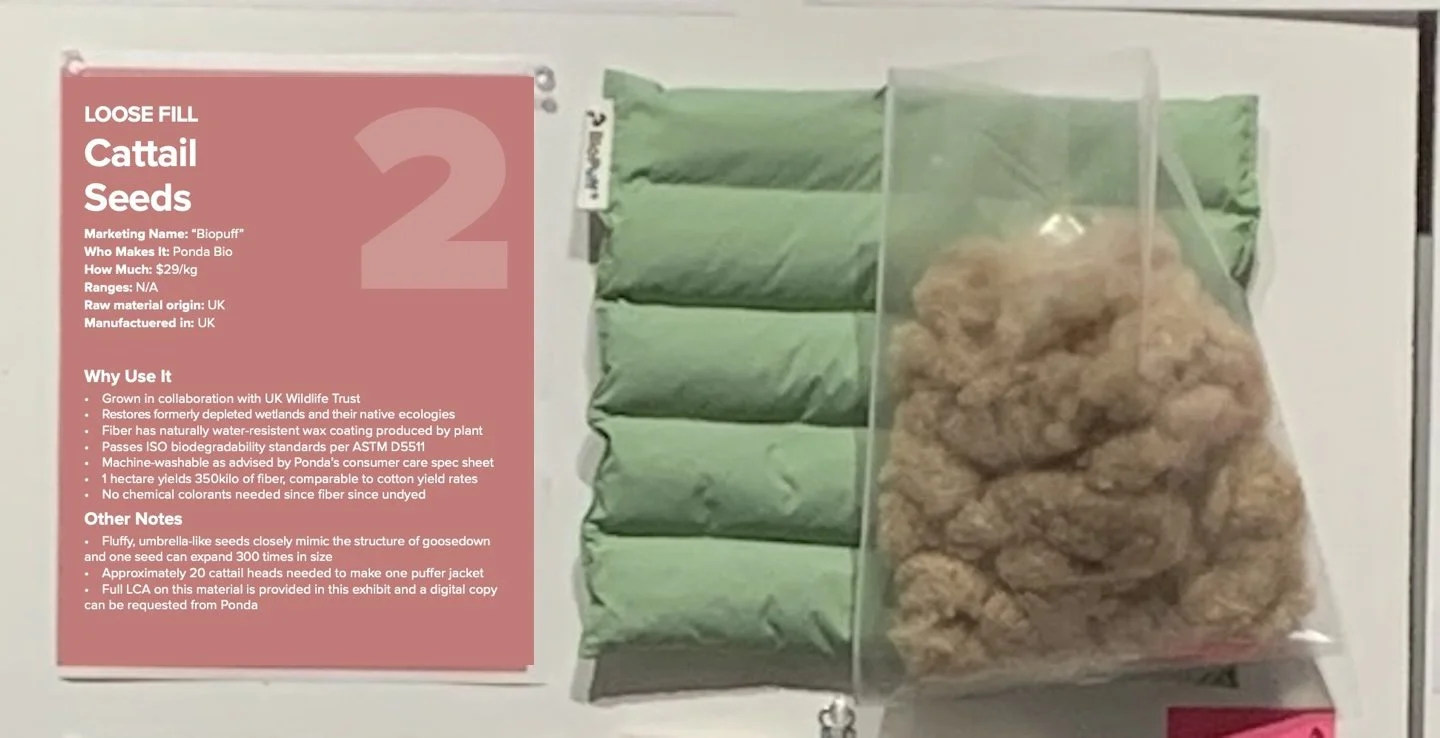

An overview of the renewable alternatives, including info on each raw material, manufacturing process, and environmental impact

A price/kg and price/yd comparison chart, comparing each renewable product’s pricing against synthetic and down benchmarks

A thermal retention comparison chart, showing CLO values (self-reported by vendor) for each renewable fiber type. I also worked with a third party testing lab to quantify other various performance metrics such as machine washability and fiber migration. However, those results have not yet been graphed.

A list of reference links at the end of this page, in case any readers want to learn more or reach out directly to these companies. The company representatives I spoke to are very kind people with an honest, ecologically-minded mission and would be thrilled to start a conversation.

The SUMMARY of my research

Problems with CURRENT INDUSTRY OPTIONS

Renewable Alternatives

performance metrics comparison

PRICE comparison

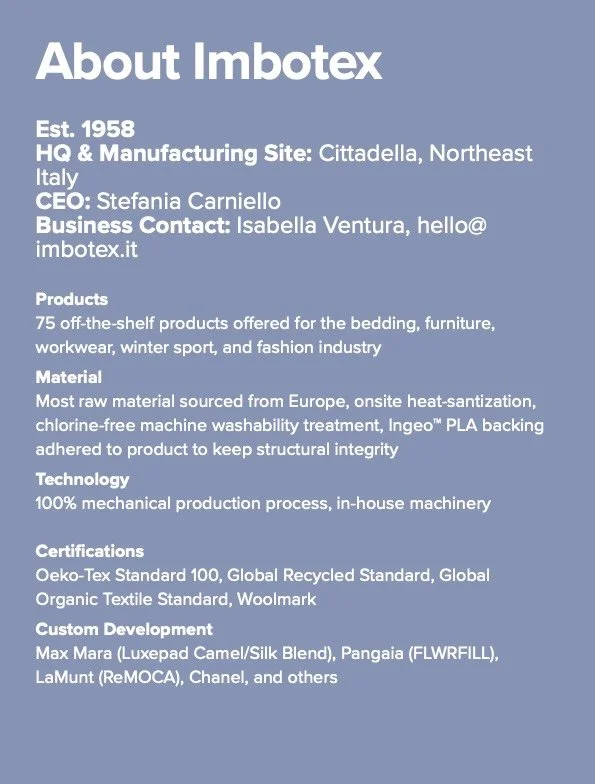

the renewable Vendors i met with

Imbotex Instagram

PondaBio Instagram